Quick Guide: What Really Drives Microbial Barrier Performance

When selecting polypropylene sterilisation packaging, there is often a debate regarding the construction of the product and the specific number of Meltblown layers. Because the meltblown layer provides the filter capacity for the wrap, it is often argued that more layers of Meltblown provide superior protection.

However, looking beyond the acronyms is essential to understand what truly drives microbial barrier performance and patient safety.

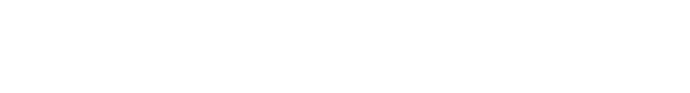

Understand the Layers: Spunbond vs Meltblown

Acronyms like SMS, SMMS, SSMMS, or SMMMMS describe the specific combination of layers used in the material:

-

Spunbond

These layers are designed to provide the material’s strength.

-

Meltblown

These layers act the filter against bacteria.

While some brands promote higher layer counts as proof of improved functionality, this number alone does not determine how well a material performs as a microbial barrier. After all, it isn’t the quality of Meltblown layers, but the quality and structure of the Meltblown that determines the microbial barrier properties of the wrap.

A Scientific Approach to Barrier Performance

To accurately measure barrier performance, a scientific approach using standardised test methods is required, as foreseen by EN ISO 11607.

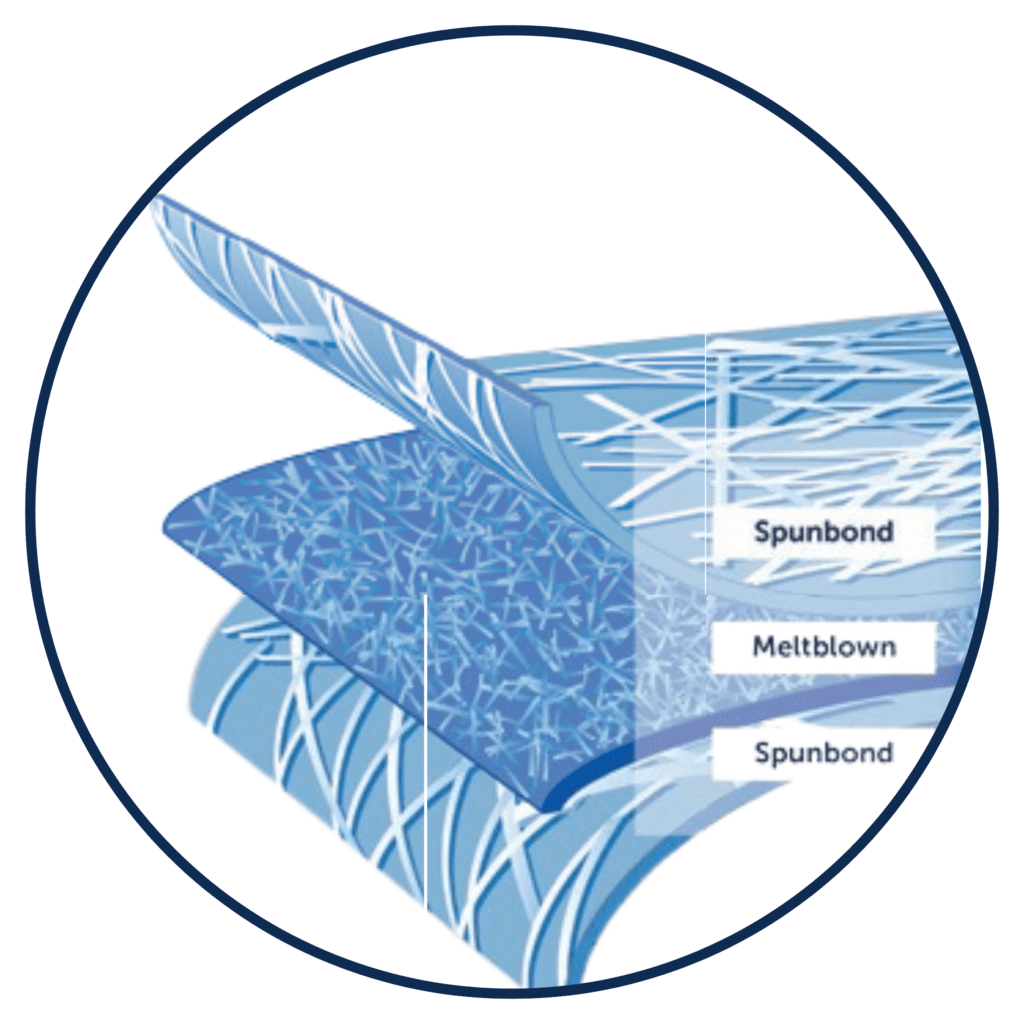

HALYARD* sterilisation wrapping products are engineered to include several Meltblown layers to support high filtration performance while maintaining breathability. Scanning Electron Microscope (SEM) images show the consistent structure of these Meltblown layers and how the interlocking fibers create a strong material structure.

The Role of POWERGUARD* Technology

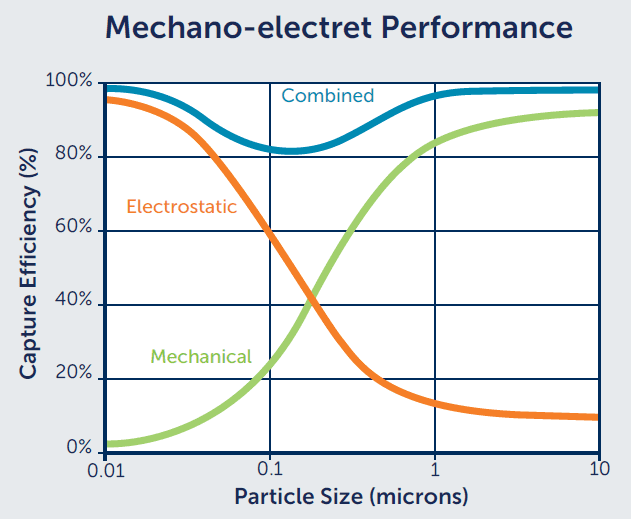

HALYARD* sterilisation wrap combines multiple Meltblown layers with proprietary POWERGUARD technology*. This is an electret technology that provides two distinct types of filtration:

-

Physical Mechanical Filtration

Provided by the fiber network itself.

-

Electrostatic Filtration

Provided by the electret technology.

The combination of these technologies delivers reliably high Bacterial Filtration Efficiency values of 99.6-99.9%

Mechano-Electret Performance Chart

Combined filtration technology delivers

99.6-99.9% Bacterial Filtration Efficiency (BFE)

Technical Data and Compliance

Performance and safety are verified through rigorous testing and compliance with international standards:

-

Standard Compliance

Compliant with EN ISO 11607 and EN 868-2.

-

Test Methods

Tested according to ASTM F2101 and ASTM F1608.

By focusing on the quality of the Meltblown structure and advanced filtration technologies rather than just layer counts, healthcare facilities can ensure a high standard of microbial barrier performance.

From examination gloves and protective gowns, to facial protection and sterilisation wraps, HALYARD* offers a clinically tested range of sterilisation solutions that are designed to protect patients, support compliance and give your team the confidence they need to perform at their best. Read more here.