Smarter Protection Starts in Sterilisation

From examination gloves and protective gowns, to facial protection and

sterilisation wraps – Halyard's clinically tested sterilisation solutions are designed to protect patients, support compliance and give your team the confidence they need to perform at their best.

Protect yourself.

Protect your team.

Protect your patients.

As a CSSD technicians, safety is essential.

At O&M HALYARD, we’re therefore committed to providing a comprehensive range of single-use infection prevention solutions made from the most advanced materials to help

protect you, your team and your patients.

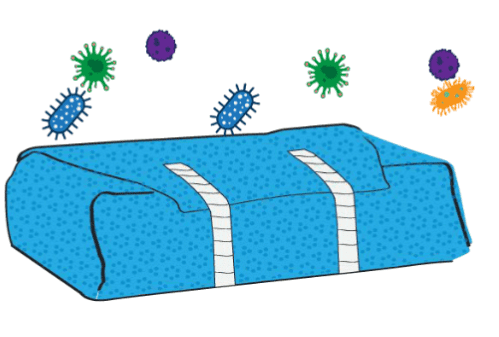

HALYARD* POWERGUARD* Technology

HALYARD* POWERGUARD* Technology Protects your trays with greater than a 99.9% barrier

All HALYARD* sterilisation packaging material is treated with the unique POWERGUARD* Technology. The HALYARD* process infuses the wrap

fabric with unique electric micro-fields surrounding the Meltblown fibres. This varied network of charged fibres forms gradients within the fabric structure, enabling it to be highly effective at microbial capture and retention, so essential in preventing fibre release of captured microbial contaminates over time.

The POWERGUARD* treatment maintains these high capture and retention properties through sterilisation, distribution and storage.

From Sterile Wrap to Medical Innovation

The GO JACK®: Circular Innovation in Sterile Reprocessing

The GO JACK® is a surgical instrument opener made from recycled O&M Halyard sterilisation wrap, proving that hospital-grade materials can be given a new lease of life.

A small device with a big environmental impact.

Developed by Van Straten Medical and endorsed by GreenCycl, the GO JACK® embodies the principles of circular healthcare: reducing waste, reusing high-quality medical-grade materials, and designing tools that return to the clinical environment.

Featured Sterilisation Solutions

QUICK CHECK* Sterilisation wrap

HALYARD* XL-transportation with SMART-FOLD* or QUICK CHECK* sterilisation wrap

SMART-FOLD* Sterilisation Packaging

Sequential Sterilisation Wrap

Sterilisation Accessories

Heat Seal Pouches and Reel

Tray Liners

- Millenium blue liners: lightweight, user-friendly, and designed with a matte blue finish to reduce glare.

- Protective Tray Liners.

Purple Transport Bags

Silicone Transport Carpet

Transportation Tray

Protection for Decontamination: Comfortable and Protective

FLUIDSHIELD* MASK

Use a combination of materials for optimal resistance to fluid penetration on impact. Available in an array of styles (earloops/ties & with/without visor), our entire range of masks meet European norms for facial protection (EN 14683:2019+AC:2019).

SAFEVIEW* EYEWEAR

These lightweight glasses, designed for the CSSD, are available in a variety of reusable colourful frames and single-use replaceable lenses, all of which can be easily worn over prescription glasses.

PURPLE NITRILE* MAX Gloves

Halyard’s extra-long, extra strong PURPLE NITRILE* MAX gloves are specifically designed for CSSD professionals. Easy to put on and offering a range of critical safety features.

Our Commitment to the Future

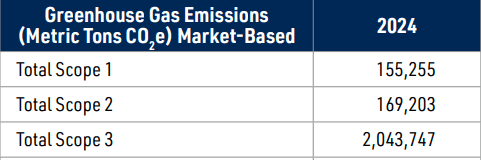

We are publicly sharing our strategies to achieve the following environmental goals:

FACILITY

At our manufacturing site in Lexington, North Carolina, we actively measure greenhouse gas emissions, water usage and waste in order to define and implement site-specific goals aimed at reducing our environmental footprint.

Owens & Minor sustainability targets are supported by the facility in the following ways:

– Recycling rates of almost 95% of all waste generated are being maintained.

– Improving energy and water efficiency through LED lighting and cooling tower enhancements

– Implementing circular processes by capturing process scrap for on-site reuse or resale to third parties who convert it into recycled resin for use in manufacturing new products.

MATERIALS

HALYARD Sterilisation Wrap* is made entirely from SMS polypropylene (PP) — a material resistant to thermal and other sterilisation modalities, widely used in medical, industrial, and laboratory settings.

Polypropylene, classified as recyclable resin #5, is a highly recyclable material. The used wrap forms a homogeneous, clean, reusable resin, making it well suited for conversion into PP pellets.

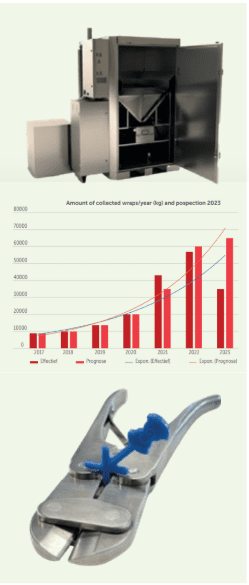

FEASIBILITY

To better understand recycling logistics, Halyard conducted a pilot project in two German hospitals, resulting in the collection of 1,500 kg of clean, used HALYARD* Sterilisation Wrap over four months.

Two different recycling companies processed the material into PP pellets suitable for use in the commodity industry.

A key takeaway was the importance of waste disposal area setup, which varies by facility — both press containers and transparent bags proved to be viable options.

3rd PARTY PROJECTS

Innovative recycling initiatives across Europe are extending the life of HALYARD* Sterilisation Wrap:

– Thermal Compaction Group (UK) developed the Sterimelt, which melts wrap into PP blocks, reducing volume by 85%, lowering storage needs and transportation emissions

– Enadvis (Belgium) collected 187 tons of wrap between 2017 and mid-2023 — equivalent to 2.3 million kilometres not driven by a diesel car

– Greencycl (Netherlands) is advancing true circularity, transforming hospital waste back into medical products, including the GO JACK instrument opener, manufactured by Van Straten Medical and endorsed by Greencycl.